Better Control Means Better Productivity

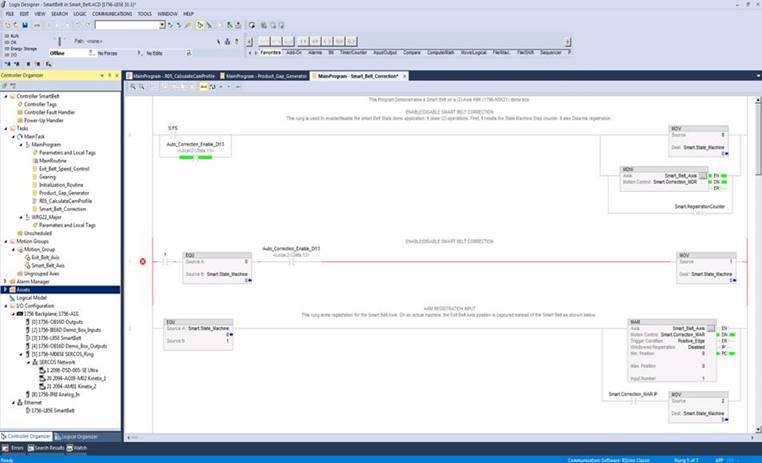

You can’t control what you can’t measure. Just knowing the parameters also isn’t enough. Its what you do with the information that matters. PLCs can decide for you. Gone are the days of operators turning knobs and pressing buttons (unless you want them to). Ideally PLC Programming Services would set up plcs to operate the plant with a single button push (start!). Further interruption or operations would be less-than-optimal.

Programmable Logic Controllers (PLC) and Programmable Automation Controllers (PAC)

Which PLC to choose? There is a trade-off between brands, features and cost. There are several low cost PLCs on the market but they have a reputation of lacking durability. A well known brand, such as Allen Bradley (Rockwell), carries the reputation of being “bullet proof,” but the cost is substantially higher. Cost of most PLCs is related to number of control points and whether there are analog signals (versus digital). Special features, such as safety related PLCs, also are more costly but have the features related to safety installations that may be required. Other popular PLCs are manufactured by Siemens, Omron, Delta-V (Emerson), Schneider Electric, and Fanuc (GE). Lower cost PLCs include Maple Systems, Automation Direct, and IDEC.

Power Tip #1: Choose a PLC that will give you the i/o that you need plus 20%.

By having 20% to spare, you may add control points in the future or swap control points if one fails

PLC Programming Services

There are companies (such as TJT Engineering) that can help you select and program your PLC. After a conversation to discuss your needs, a PLC system can be recommended. To discuss your situation with TJT Engineering, click here: TJT Engineering Contact

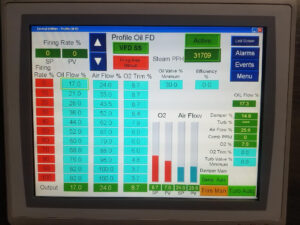

HMI Systems

Adding an HMI: So you want to add an HMI to your system?

When and where to add an HMI to your system is a question that takes some contemplation. They are not especially cheap but they can add so much functionality in control. What do you need to monitor or control? And where? These are the typical questions one must ask. Once you start adding HMIs, they can also help permeate the control throughout the facility (i.e. one area could control several others if you desire.) There several brands of HMI programming software but most function approximately the same. Cost usually varies on how many control points or screens are desired.

The other big question is, “how big of a screen do you need?” Size matters. A larger screen and higher resolution make it possible to add more data and makes it easier for the operator to see what is going on. The trade-off is that larger screens and higher resolutions cost more than smaller screens and lower resolutions.

Where is the screen going to be installed? An office setting is less harsh on electronics than a production floor. Does the screen need to be in an enclosure? Is the screen exposed to the elements? An all-in-one PC can serve the purpose in a low exposure environment but would not be recommended anywhere else.

Power Tip #2: Don’t shortchange the HMI: a good HMI will add to operator satisfaction.

How to choose PLC Programming Services

The easy answer is contact TJT Engineering (yes I see you rolling your eyes). The fact is that we can help you decide even if you don’t go with us. We can also help you know what to look for. Perhaps you want to find “PLC programming services near me”. Depending on the size and scope of your project, it may make sense for us to travel to meet you. In any case, let’s have a discussion. Start the conversation here: TJT Engineering Contact

One other company that provides PLC Programming Services is DMC

SCADA and Instrument Integration

One other thing to consider is choosing PLC programming services is instrument integration. TJT Engineering has a lot of experience recommending instruments and integrating them with PLCs. We can help you figure out what to monitor, how to monitor it and how to integrate the information. Total system integration and monitoring will help you get the most out of your system.

Power Tip #3: maximize your production and operator satisfaction by implementing high quality automation. Higher production means higher profits to help you dominate the market.